| TESTING TWO

TIGERS

continued

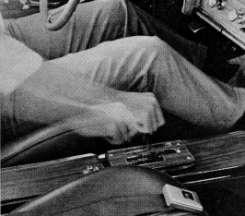

4- speed shifter seems more business like without

console. Wood wheel adds class.

Hurst Hydro-Shifter is available only with console, and

offers firm, positive shifts.

Storage area in console is easily reached from either of

the comfortable buckets. |

gave

firm, precise control at all times. Standard equipment Wide-Oval tires

plant themselves firmly to the road, do- ing their bit for good handling.

This car stopped like it had front-disc brakes but a quick look underneath

un- covered drums. Recalling the sad drum brakes on last year’s car, we

couldn’t get over how straight and quick the new ones worked in wet

weather and dry. It is one of the few cars we’d buy and not insist on

disc brakes. The two cars schedu1ed for perfor- mance testing and the

unmodified GTO were all equipped with 360-hp, 400- cubic-inch V-8s with

Ram-Air kits. We purposely left them outside and under- neath trees during

rainy spells, to find out how much garbage we’d collect through the

functional air scoops in the hood. Nothing – not even a twig – managed

to find its way through the rather small hood openings. A paper element

air filter would have stopped junk from getting into the engine, but would

clog in the process. The Ram- Air kit includes the functional air scoops,

a pan which fits around the carb opening and is sealed to the hood with a

foam rubber lip, and a cam with longer duration intake and exhaust lifts.

The valve springs on Ram-Air engines are much stronger than on the regular

360- hp engine. Triple carburetion is no longer avail- able for GTO’s

but the single Quadra- jet-carbureted engine of 360 hp, while maybe not as

strong a status symbol, is the equivalent or better in performance.

Ram-Air is available only with this largest-of-all powerplants. You’ll

be glad to know that parts from the new 400-cubic-inch engine will bolt

onto the old 389-cubic-inch engines, so ’67 heads will probably find

themselves on many 389 blocks. They have larger valves, relocated valve po-

sitioning, improved combustion cham- bers and larger ports. The new free-

flowing intake manifold will fit earlier engines, but more likely,

there’ll be a lot of last year’s 3-2 manifolds going on ’67 engines.

Cast-iron exhaust mani- folds with individual runners are a feature of the

’67 engine and will ade-. quately serve those who do not wish to install

custom tubular steel headers. Almost as soon as GTO buyers leave any

dealership, they start improving their cars. A surprising number of street

driven ”Tigers” have been modified to make them competitive at weekend

drag events as well as suitable for daily trans- portation. We felt if we

tested a pair of ”fresh” cars, performance would prob- ably be below

this abnormal average. This reasoning prompted our requesting Milt

Shornack to outfit the test cars to this dual-purpose standard. One of his

first steps was to install Royal’s own ”Bobcat Kit.” The kit is

basically a tune-up package and in-

|

|

cludes

thinner head gaskets to raise compression closer to the allowed (and

advertised) 10.75: 1 ratio. Also includ- ed are heat-riser blocked intake-mani-

fold gaskets, lock nuts for the rocker arms which allow the hydraulic

lifters to be adjusted full height, .050-inch larger primary jets for the

carburetor, and instructions on how to get the vac- uum-controlled

secondaries to open quicker. Rounding out the kit is a com- plete ignition

set which contains lighter springs and weights – with positive stop to

guard against too much advance – and a full set of tailored spark plugs.

This kit is easily installed and sells for about $70. It’s available for

all GTOs and can shorten quarter-mile times by as much as a half-second.

Technically, the installation voids the drive train warranty, but then, so

does Sunday drag racing. Pontiac, however, tends to be rather liberal in

its policies because it knows what sells GTOs. Both cars were also fitted

with Hurst, individual-port, equal-length, exhaust headers. These were the

first two sets produced by Hurst and they worked beautifully. Hurst is

just now entering the header business and will offer them to fit all

popular performance cars. Suspensions were not touched in any way, and the

highly-tuned engines were quite docile at all highway speeds, con- vincing

us that alterations such as these don’t affect work-a-day utility of a

prep- ped car. The running gear, except for the transmission, was

identical with 3.90: 1 limited-slip differentials housed in the

heavy-duty, extra-cost, rear-end assembly. Each car had front disc brakes,

and hood-mounted tachometers. Using Motor City Dragway we made a few

passes with the exhaust system closed up and street tires on the rear. The

good elapsed times and high speeds were an indication of better things to

come, but before we did any changing around for quarter-mile running, we

ran our brake tests. We first ran the cars with front-disc brakes and were

fairly happy with the results. But when we brought the drum- braked car to

a halt from 60 mph, we weren’t quite sure what happened. It stopped like

a glue-papered Ay, some 15 feet faster than the disc-brake ver- sions.

This had never happened to us before and needed explaining. Finally we

remembered that while installing the headers, the brake-pressure equal-

izer had to be moved rearward on the frame to clear the new plumbing. Ap-

parently, we didn’t bleed all the air out afterward, or else during

relocation we may have disturbed the balance in the equalizer system. The

front discs locked up much sooner than normal. There was no time to check

the system out, nor was there another car with disc brakes available for

testing, but we do feel that the stock disc set-up will stop in at least

|